There are numerous obstacles in freight shipping — especially when you’re shipping containers overseas. Everything has to be carefully planned and executed to ensure your cargo arrives on time and in one piece.

Fortunately, you can mitigate some of the risks of shipping containers overseas. Choosing the right shipping container and using innovative solutions from Eurolog Packing Group can help you safeguard your bottom line.

In this guide, we’ll take an in-depth look at shipping containers overseas, the risks involved, and what you can do to protect costly goods.

Shipping containers are used to transport large volumes of cargo by cargo ships, cargo planes, trucks, and trains. Individual containers are loaded and secured before being loaded onto the vessel that’s transporting them. When containers arrive at their destination, they’re unloaded so they can be reused.

Many container shipping companies will provide shipping containers for you, but you can also use your own containers.

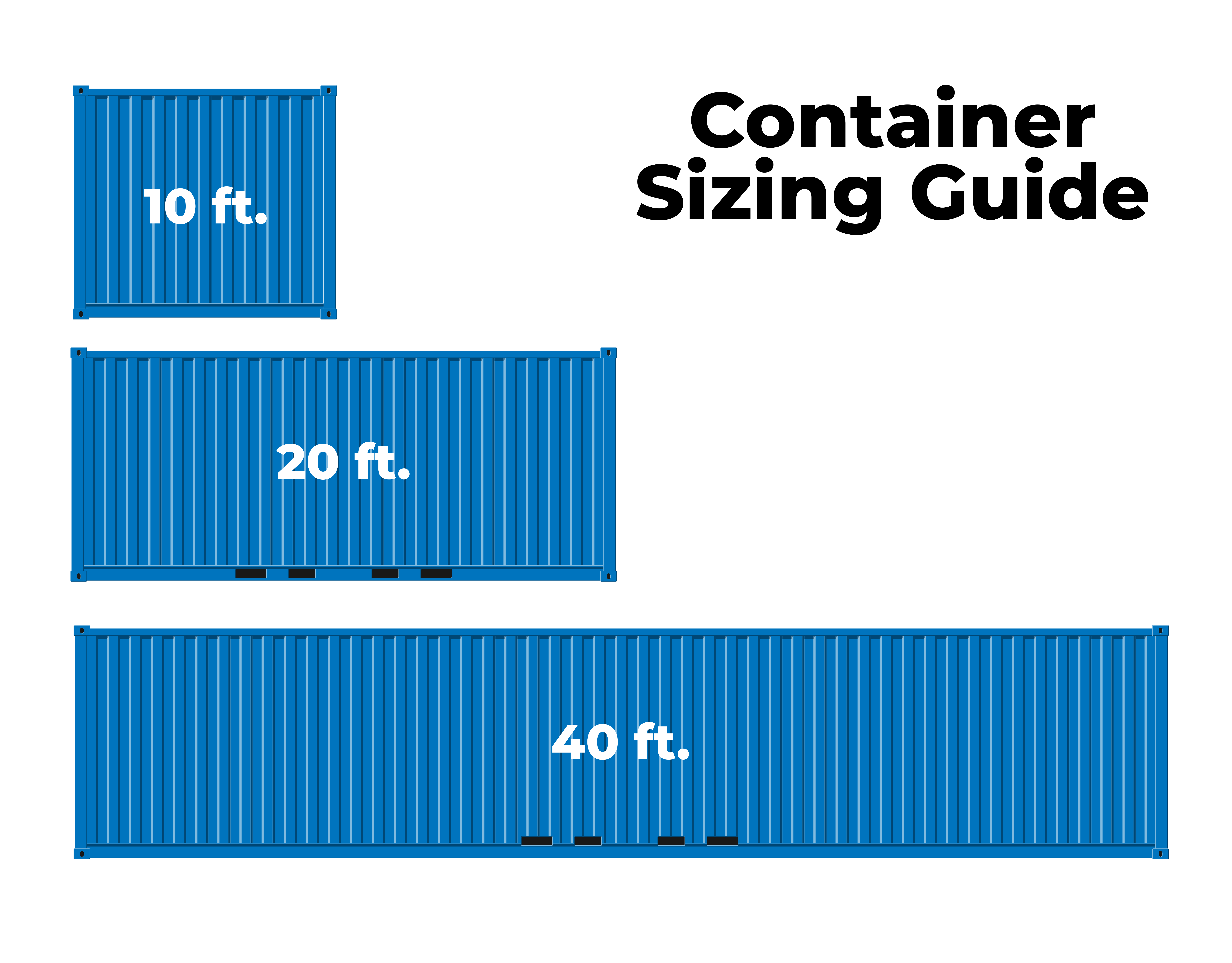

There are three common shipping container sizes — 10 ft, 20 ft, and 40 ft. Shipping containers can hold large volumes of goods, but the value of those goods depends on what you’re shipping.

According to industry experts, the average value of a 20 ft shipping container is $54,500, while the average value of a 40 ft shipping container is about $109,000. If a mere 10% of your cargo is damaged, it can cost you thousands of dollars.

Whether you’re shipping food and beverages or pharmaceuticals, shipping containers overseas puts your cargo at risk. Let’s explore some of the common risks of container shipping so you know what you’re up against.

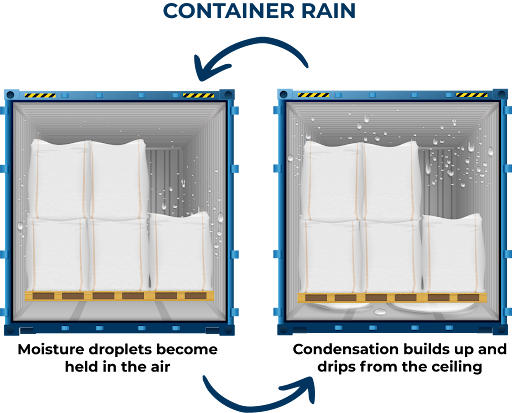

Moisture damage is the leading cause of cargo damage worldwide. From leaks and spills to container rain, moisture damage accounts for a significant portion of the damage sustained by cargo across the globe.

Leaks and spills are common issues when you’re transporting liquids. A single container of liquid leaking can introduce enough moisture to cause mold growth and other moisture-related problems. Absorbent pads can help minimize the damage caused by leaks and spills.

When condensation collects on the ceiling of a shipping container, it can build up and begin to drip down. This phenomenon is known as container rain. Container rain is one of the leading causes of cargo damage worldwide.

Changing climates and loading and unloading conditions can lead to excess moisture in shipping containers, so preventing moisture-related problems is a priority.

When you’re shipping cargo from one side of the world to the other, changing climates are an issue. Whether you’re transporting cargo south of the equator or near the North Pole, extreme temperatures can cause problems.

Warm climates are a big problem when it comes to food, beverages, and pharmaceuticals. These products can spoil when exposed to extreme heat, and extremely cold temperatures can lead to quality concerns.

Extreme heat isn’t the only concern when shipping containers overseas — extreme cold can also pose a risk. Certain chemicals and medications can react to especially cold temperatures, making them less effective.

Container ships carry thousands of containers, and individual containers can be filled with various types of cargo. With sensitive cargo like food and medication, contamination is a huge concern when it comes to shipping containers overseas.

When chemicals and other liquids leak, they can contaminate other products. Dirt and other contaminants can also get into shipping containers when containers are being loaded and unloaded. If there’s a major problem during loading or unloading, it can lead to severe contamination.

Dry bulk goods are especially susceptible to contamination. If you’re shipping large amounts of grain or seed, you need to separate your goods from other goods that may pose a risk of contamination.

Standard shipping containers are the most common choice among manufacturers and suppliers, but there are several types of shipping containers. Find out more about some of the different types of overseas shipping containers below.

Reefer containers are also known as refrigerated containers, and they’re specially designed to keep temperature-sensitive goods cool. Reefer containers are equipped with a refrigeration unit that keeps your cargo cool even when it’s exposed to extreme temperatures.

The food and beverage and pharmaceutical industries are two of the most popular use cases for reefer containers. However, reefer containers can be used for any cargo that needs to be kept at a stable temperature — including vaccines, organs, and tissues.

Reefer containers are more expensive than dry containers, so you can expect to pay more if you want to ship your cargo in a refrigerated container. When you’re deciding on a container, consider the potential cost of cargo damage versus the cost of upgrading to a more secure container.

If you’re shipping liquids or any other goods that are usually transported in a tank, tank containers are an excellent option. Tank containers can be used to transport liquids, gasses, and powders across the globe safely.

Most tank containers are equipped with simple loading and unloading valves, so it’s easy to fill your container with whatever you need to transport. Tank containers also feature pressure relief valves so built-up pressure from gasses and liquids can safely escape.

There are different types of tank containers, including food-grade tanks and reefer tanks. Tank containers make shipping containers overseas simple — even if you’re shipping liquids or gasses.

Shipping containers overseas comes with several risks, but you can protect your cargo with a few simple tips. Using the right packaging and protecting your cargo from extreme temperatures and moisture can save you a significant amount.

Choosing the right packaging is one of the biggest keys to ensuring your goods arrive safely. No matter what you’re shipping, there’s a particular type of packaging that’s designed to protect your cargo.

Food-safe packaging is essential for foods and beverages. This packaging is made with materials that won’t contaminate food. There’s also medical-grade packaging for pharmaceuticals and other medical products.

If you’re shipping goods with a high moisture content, you may want to avoid using wood pallets. Plastic pallets absorb less moisture, making them an ideal choice when you want to mitigate moisture-related problems.

Desiccants are the most useful resource when it comes to preventing moisture damage when shipping containers overseas. Desiccants absorb excess moisture from inside your shipping container, reducing the risk of container rain moisture damage, and mold.

Our Hybag desiccant bags offer a simple moisture control solution. Hybags hang from the inside of your shipping container and absorb excess moisture from the air, protecting any sensitive goods in your container. The Hybag Plus+ offers even better absorption, and we also offer custom solutions that are tailored to fit your needs.

The Hyblanket protects against container rain, which is a leading cause of cargo damage when shipping containers overseas. Simply attach the Hyblanket to the ceiling of your shipping container to absorb excess moisture and prevent container rain.

If you want to prevent leaks and spills, our Hypad is an excellent solution. Hypads sit beneath your cargo to absorb any liquid from leaks or spills, making it easier to safely ship beverages and chemicals.

We also offer custom Hydry solutions like Hydry DoorAbsorb. DoorAbsorb creates a protective barrier around the door of your shipping container, ensuring no moisture from another container — or the surrounding air — gets into your shipping container. Customer Hydry products are available in different shapes and sizes.

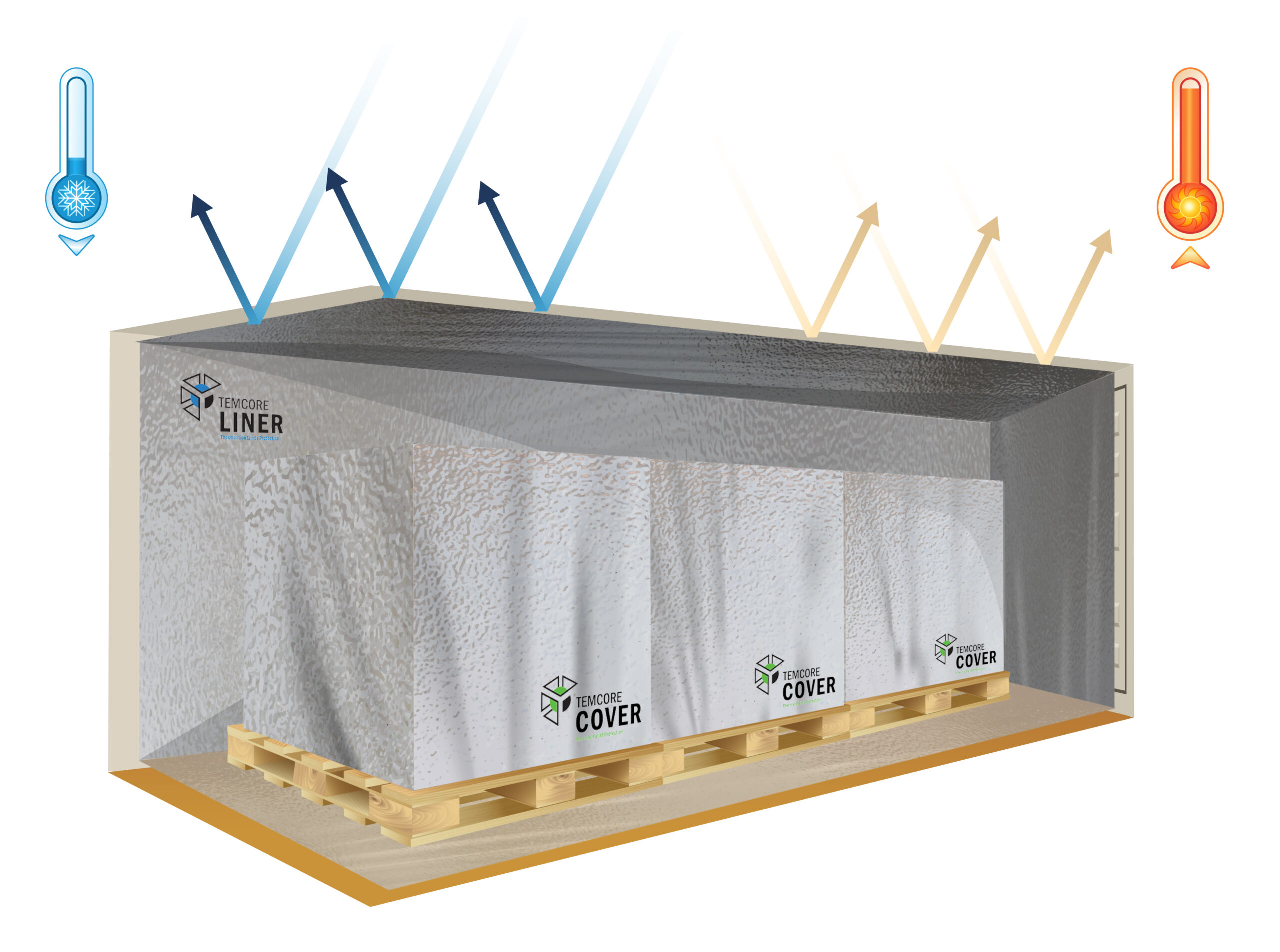

Extreme temperatures can significantly damage your cargo, especially if you’re shipping consumable products. Insulating your shipping container — and the goods inside it — is a great way to prevent damage caused by moisture and extreme temperatures.

You can maintain stable temperatures inside your shipping container with a Temcore liner. Temcore container liners are made with a high-grade aluminum lining that reflects up to 97% of radiant heat. We have several Temcore products to choose from, including thermal blankets, container liners, and pallet covers.

For maximum protection, you can cover individual pallets with our Temcore Max Cover. The Temcore Max Cover holds temperatures within 1 degree per hour, keeping frozen goods and other sensitive items safe during transport.

Ensuring your goods arrive safely and on time is a lot of work, but innovative packaging and shipping solutions can help. Whether you’re shipping agricultural products or pharmaceuticals and medical products, there are solutions designed to meet your needs.

At Eurolog Packing Group, we specialize in developing innovative shipping solutions that simplify shipping containers overseas. From moisture control to temperature stabilization, we can help you solve international shipping challenges.

We can even customize our shipping solutions to match your unique needs. Whether you need Hydry products in custom sizes or another custom solution, we’re here to help.

If you want to eliminate the stress of shipping containers overseas, contact us to learn how Eurolog Packing Group can help.

Sandra Malouf is the President of Eurolog Packing Group and has spent her career focused on Industrial Packaging. With a proven track record of helping businesses avoid supply chain disruptions, Sandra’s visionary leadership elevates the industry. She’s committed to developing sustainable practices and continues to shape the future of industrial packaging by listening to the customer and offering unique solutions applicable to various industries across the world. The company’s main focus is temperature stabilization and moisture damage prevention in exports affected by extreme variations in global temperatures.

© 2025 Eurolog Packing Group