How a Global Leader in Hygiene

Used Kit Bond and Hyblankets to Solve the Mold Issue in Exports

THE ISSUE

A global leader in the hygiene industry reached out to our company in 2023, facing a severe problem with mold growth on boxes during transit from China to various ports in the USA. The company was compelled to halt all inbound containers into the USA until they could resolve the issue.

This meant warehousing inventory for 1,500 containers for several additional months until they could resume their export plan. Consequently, unexpected warehousing costs of over $50,000 per month for these specialty items were incurred, leading to a disruption in stock for various USA retailers.

OUR HYPOTHESIS

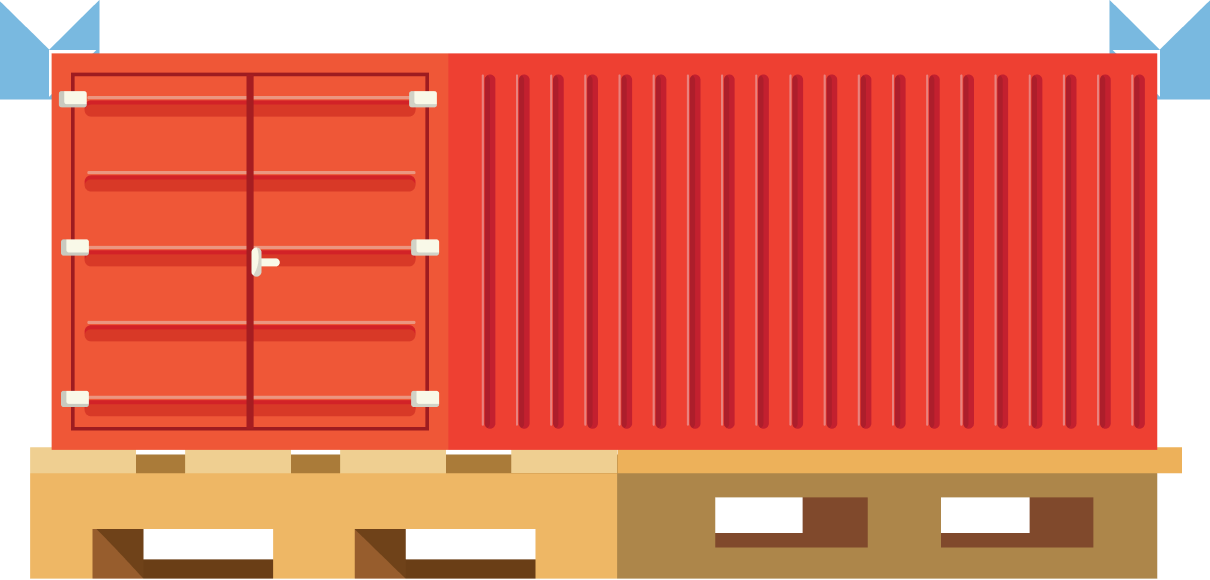

After engaging in discussions with the supply chain team and understanding the issues at hand, we formulated a hypothesis. Since mold growth predominantly occurred along the boxes adjacent to container side walls and in direct contact with the pallet, we theorized that temperature variations during the container's journey were causing excessive condensation on the container walls. This moisture, dripping onto the container floor combined with the moisture content of recycled boxes (averaging 35%), created an environment conducive to mold formation.

The Solution

Upon consultation with the Quality Team, it was agreed to conduct a trial using our Hypad and Kit Bond products. The Hypad was positioned over each pallet to shield the shipped goods from floor moisture and pallet-based moisture. The Kit Bond served as a barrier between goods shipped adjacent to container side walls and the container walls, absorbing condensation instead of it being absorbed by the boxes.

The initial trial encompassed 40 containers shipped from Asia to the USA. Data loggers were installed in each of these containers to measure temperature and humidity throughout the journey. Each shipment included 40 double-stacked pallets of hygiene products. Hypads were placed over the 20 bottom pallets, and Kit Bond covered the floor and walls.

Warehouse Costs Saved

Containers Shipped

Mold Issues

The Results

The data confirmed that condensation (cargo sweat) occurred at various points during the 4-week journey. Condensation in shipping containers happens when the container walls become cooler than the dew point of the air inside. As shipping containers are metallic, external factors and weather changes can cause internal temperature shifts. The trial also demonstrated the effectiveness of Hypad and Kit Bond in absorbing condensation, eliminating the mold issue on the boxes within the container. The Quality team approved the products for use in all export containers, resulting in 1,200 containers arriving without issue, with 300 more scheduled before the year-end.

Contact Us

© 2024 Eurolog Packing Group