What Causes Container Rain?

Eliminating moisture is one of the biggest cargo shipping challenges. Enclosed metal shipping containers aren’t completely airtight, and changing temperatures and weather conditions can introduce moisture to your cargo.

So what can you do? Preventing the build-up of moisture inside shipping containers is the key to preventing container rain. Properly ventilating your shipment and using desiccants can protect your cargo from excess moisture.

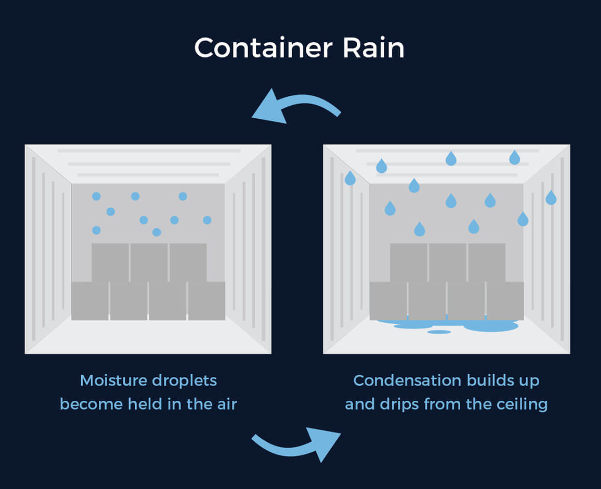

Container Rain

Container rain is a phenomenon that occurs when moisture builds up inside a shipping container. This moisture buildup occurs as a result of changing temperatures inside the shipping container which causes air to expand and contract. As the moisture rises to the top of the shipping container and sticks, it begins to fall onto the cargo inside your shipping container.

The root cause of container rain is impossible to avoid. Shipping containers are loaded and unloaded near the ocean, and they’re also transported across the ocean to their destination. Because the ocean air has more moisture, it can cause a buildup of moisture inside your shipping containers.

The Cost of Container Rain

There are several potential consequences when moisture gets into shipping containers and makes contact with your cargo. Some cargo may mold or rot when exposed to moisture, while metal and wood can warp or rust. As a result, entire shipping containers of cargo can be lost to container rain.

The cost of container rain is precisely why it’s so important to protect your shipments. It may cost money to prevent container rain, but that’s nothing compared to the losses you can suffer if your cargo is exposed to a high concentration of moisture during shipping.

Preventing Container Rain

The good news is that there are steps you can take to prevent container rain. Choosing the right shipping container and using smart packing materials can help you keep moisture from building up in your shipping containers. We’ll talk about some of the best ways to prevent container rain below.

Use non-absorbent crates and boxes

Wood crates and corrugated boxes are more susceptible to moisture because they’re absorbent. When you’re packing up your cargo to load in your shipping container, choose non-absorbent crates. Plastic crates are an excellent choice if you’re looking for sturdy crates that won’t absorb moisture.

You should also be mindful of how you’re loading everything up in your shipping container. If you’re shipping absorbent packages or materials, try to separate them from non-absorbent crates so you’re not exposing the contents of those crates to moisture.

Wrap boxes in plastic

If you’re shipping cargo that’s sensitive to moisture, you can wrap it in plastic to prevent container rain. Plastic is non-absorbent, which means it won’t absorb moisture and allow it to get inside your crates and boxes. Shrink-wrapping your cargo before you load it up is one of the easiest ways to prevent moisture damage caused by container rain.

Keep in mind that your cargo should be fully dry before you wrap it in plastic. Wrapping moist cargo in plastic can cause it to mold because the moisture has nowhere to escape through the plastic barrier.

Use desiccants

Desiccants are used in everything from beef jerky to shoes — and they can be used to lower the relative humidity (RH) in the air to reduce the risk of container rain. Using desiccants in your shipping containers can help prevent moisture from building up, which reduces the risk of mold, corrosion, and bacteria growth.

Shipping container desiccants are easy to use, so you should be using them to protect every potentially sensitive shipment. You can simply hang desiccant bags throughout your shipping container to absorb moisture and prevent container rain.

Hydry containers and bags from EPGNA are a simple way to prevent excess moisture from building up in your shipping container.

Use insulation

Using insulation can help you maintain consistent temperatures inside your shipping container, which lowers the risk of container rain. You can install permanent insulation to avoid having to insulate all the cargo you put in your shipping container, and there are several products designed specifically for containers.

Container insulation can also help protect temperature-sensitive shipments from damage that may be caused by extreme hot or cold temperatures. If you’re shipping moisture or temperature-sensitive cargo, insulation is a must.

Ventilate your shipment

There’s only so much you can do to absorb moisture and control the temperature within shipping containers. One of the best things you can do to prevent container rain is to properly ventilate your shipment. Proper ventilation allows moisture to escape, so it doesn’t build up on the top of your shipping container and rain down on your cargo. You can add vents and mechanical fans to make sure every shipment is properly ventilated.

Purchase insurance

At the end of the day, there’s only so much you can do to protect your cargo. Container rain and other types of damage happen, so purchasing insurance is one of the best ways to avoid serious financial losses caused by container rain.

Container insurance may seem expensive, but it’s nothing compared to the cost of losing or damaging expensive cargo. If you can afford it, make sure you’re protected with container insurance.

Trucking

The need to prevent container rain doesn’t just stop at vessel shipping. Once the shipping container makes its way off the dock it can be transported one of two ways: trucking or freight. Trucking makes up the majority of domestic shipping and has some unique problems. For example: you might be shipping bananas from the Dole plantation in Hawaii to San Diego, California. Only when the shipping containers arrive, one is headed for Colorado—in the middle of winter. It’s never a bad idea to have your container lined and prepped for its final destination during the initial container loading. With goods that spoil, prepping for domestic shipping is essential to preventing loss and damage.

Freight Shipping

According to the U.S. Census Bureau, freight shipping has increased steadily over the last 15 years as the population has increased. Every day, 5 million tons of goods are delivered via the U.S. railway system. Freight and railway make up almost half of all domestic shipping. Damage from freight shipping occurs mostly due to temperature changes. With the majority of the U.S. railway system in the south, products coming from cooler climates are exposed to rapid heating from the warmer southern climate.

Protect Your Shipment With Eurolog Packing Group

Container rain can cost you thousands of dollars. If you’re shipping cargo in shipping containers, you need to know how to protect against container rain. There are several possible solutions, including desiccants, insulation and insurance.

Need help preventing container rain? EPGNA offers several innovative solutions, including insulation and desiccant bags. Contact us today or check out our shipping solutions to learn how we can help you protect your cargo.

Sandra Malouf is the President of Eurolog Packing Group and has spent her career focused on Industrial Packaging. With a proven track record of helping businesses avoid supply chain disruptions, Sandra’s visionary leadership elevates the industry. She’s committed to developing sustainable practices and continues to shape the future of industrial packaging by listening to the customer and offering unique solutions applicable to various industries across the world. The company’s main focus is temperature stabilization and moisture damage prevention in exports affected by extreme variations in global temperatures.

© 2024 Eurolog Packing Group