No matter what you’re transporting, shipping goods by sea, land, or air can be costly. And if your items sustain damage during transit, those costs can continue to add up; defective products and rejected shipments from unsatisfied recipients can impact your bottom line.

Of all the concerns related to overseas shipping, moisture is the primary cause of product damage. Some estimates show that up to 10% of all containerized goods sustain enough moisture damage to warrant being discarded.[1]

Smart packing solutions like shipping container desiccants can help protect your items from moisture damage during transit. In this guide, we’ll explain what shipping container desiccants are, how they work, and the benefits of using them when shipping via freight.

A shipping container desiccant is a type of shipping material used to mitigate humidity and prevent water damage inside shipping containers. Moisture buildup is especially common during sea freight transportation, though it can also occur during land and air shipping.

Shipping container desiccants generally come in the form of bags filled with absorbent materials. Desiccant bags and other desiccants draw moisture from the air inside the shipping container, helping to eliminate the buildup that can form within. This moisture buildup is often called “container rain.”

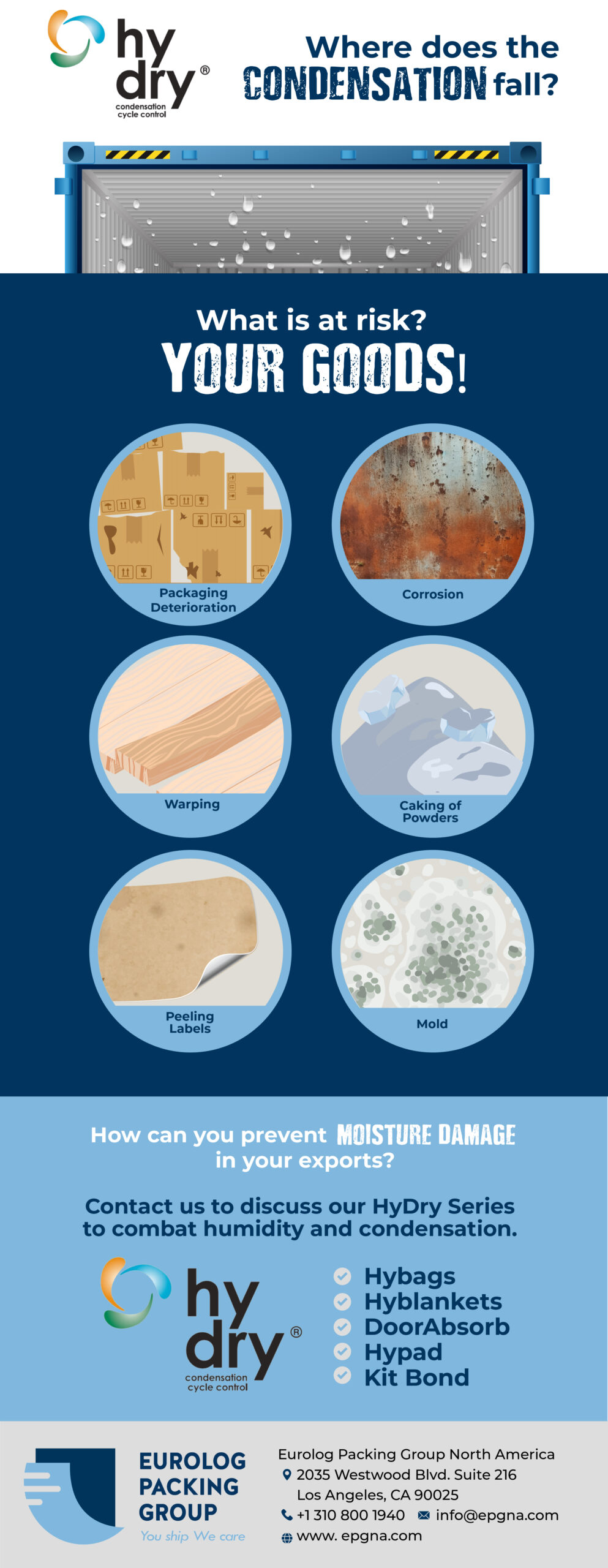

Container rain happens when moisture in the air condenses in the cooler areas of the shipping container. When temperatures shift, water starts accumulating on the container’s sides and roof. Eventually, the water droplets may become heavy enough to fall like rain. Container rain is becoming more common given containers sitting in ports longer and the extreme temperature variations they experience during the transit time.

Container rain can expose your entire container of goods to harmful moisture. Over several weeks or months, this excess moisture can lead to:

Ultimately, any exposure to moisture can be extremely damaging to the contents of your shipping container and may cause value depreciation or a total rejection of your shipment.

As you can see, the potential for cargo damage is extremely high and, as a result, very costly. Hybag shipping container desiccants can help target moisture exposure at the source and minimize its risk.

The exact mechanism behind a container desiccant’s function depends on the media inside the bag. With that said, most desiccants rely on a process known as adsorption.

Unlike the similarly-named phenomenon of absorption (where one substance passes into another), adsorption occurs when one substance clings to another. In the case of a container desiccant, the moisture in the air loosely adheres to the material inside the desiccant bag. Even though the moisture isn’t fully absorbed, it remains trapped by the desiccant for the entire voyage.

By pulling moisture out of the air and holding it, desiccants lower the possibility of container rain.

Hybag container desiccants are chemically inert and FDA approved, making them safe to use with a variety of products, including:

The media inside desiccant bags and pads helps mitigate moisture, but not all desiccants are equal. Some popular types of desiccants include:

Different types of desiccant materials can absorb different amounts of moisture. Food safety can be another key factor to consider when choosing a desiccant.

Eurolog Packing Group offers several fast-acting gel container desiccants, all of which are designed to absorb moisture slowly and protect your goods for the entire journey. We offer four different Hybag desiccant products for any situation:

You can use Hypad absorbent pads to protect against shipping container leaks and spills. Simply place a Hypad beneath any cargo that you’re concerned about spilling or leaking. If liquids leak out, the Hypad will quickly absorb that moisture to prevent condensation and container rain.

Our Hyblanket is an easy solution for container rain. Hyblankets can be draped from the top of your shipping container to mitigate built-up moisture that leads to container rain. The included fastening system makes Hyblanket easy to install.

Hydry DoorAbsorb creates an absorbent barrier to protect one of the most vulnerable parts of shipping containers: the door. DoorAbsorb can help you mitigate moisture when you’re transporting sensitive freight through changing climates.

We also offer custom Hydry solutions. Our shipping container desiccants are available in tons of shapes and sizes, and we can customize desiccant bags or pads to meet your unique needs.

Container desiccants offer an effective solution for anyone looking to protect their cargo during lengthy voyages. With that said, keeping your shipment dry isn’t the only advantage of using a desiccant. Here are five benefits of using shipping container desiccants and their applications.

Naturally, the primary benefit of a container desiccant is cargo protection. By minimizing the potential for moisture damage, desiccants help ensure the integrity of shipped goods.

Avoiding product damage is paramount, as spoilage and quality degradation contribute directly to financial losses. When items in a shipment arrive damaged, the shipping party typically eats the cost of the items as well as the additional costs associated with shipping new products.

What’s more, while the average amount of products lost due to moisture damage is 10% per shipment, some containers can arrive with 50% or more of the cargo destroyed. One damaged shipment is a costly mistake you can learn from, but when persistent issues crop up, they can seriously impact your organization’s profitability.

By addressing the source of damage from the start and including container desiccants, you can greatly reduce the likelihood that your shipment will face exposure to moisture in transit.

The global economy depends on global imports to make everyday items—such as groceries, cleaning chemicals, auto parts, and agricultural products—accessible to consumers. With so many products crisscrossing the globe, your cargo could be transported along with products from other categories, including those listed above.

When your goods aren’t properly packaged or protected from hazards like moisture or temperature changes, the risk of cargo contamination increases. Cargo contamination occurs whenever goods are exposed to potentially dangerous substances. This exposure can lead to damage or threaten the safety of people and other cargo on board.

By employing leak-proof cargo desiccants, you can reduce the potential for cargo contamination, protecting your shipments and those of others.

Because organizations have accepted that a certain percentage of goods will succumb to damage during transit, many companies overproduce goods to account for losses. With a desiccant solution protecting cargo from damage, organizations can use less raw material and manufacture fewer goods overall.

Avoiding moisture damage also means keeping defective goods out of the landfill. All too often, products that can’t be sold are disposed of “as is,” even though they should be separated for recycling.

Lastly, taking measures to deal with container moisture can help extend the life of the container itself. Over time, shipping containers exposed to moisture can rust; eventually, these corroded containers need to be retired. Although retired containers can be processed for recycling, crushing and reusing the metal can be energy-intensive. As such, keeping a container in optimal condition through the use of desiccants is the most sustainable choice.

While container desiccants may require a small upfront investment, they can help you avoid the more significant expenses associated with moisture-damaged goods. As long as you purchase the right type and number of desiccants, these shipping solutions can save you thousands of dollars on every shipment.

Our desiccant solutions come in various shapes and sizes, allowing you to protect small and large shipments without overspending or underspending. For more particular use cases, we offer custom options designed to suit any shipment.

Most container desiccants are exceptionally simple to use. For example, Hybag desiccant bags for shipping containers come with a cutting-edge hook for quick and effortless installation. In seconds, you can add a desiccant bag to your shipping container that will protect your goods for weeks.In addition, the specialty design allows for maximum absorption given desiccants are not all created equal.

Container desiccants may eliminate excess moisture, but they can’t safeguard against every possible issue. Adding ventilation, bracing, and other shipping products to your container can further protect your shipments from potential damage.

At Eurolog Packing Group Worldwide, we offer a variety of ready-made and custom solutions to protect your cargo from contamination, temperature fluctuations, and more. Our packing solutions include:

Whenever you ship cargo, damage can occur throughout the transit journey. From mold and rough handling to pests and chemical contaminants, there’s always risk involved with sending cargo overseas—whether it’s being transported by air or by boat.

With that said, moisture is the number one cause of cargo damage. But when you use container desiccants, you can mitigate the risk of water damage in every shipment. Desiccants help you avoid the extra costs incurred by damaged shipments and ensure your items arrive in perfect condition.

Ready to start shipping? Contact us today to learn about our shipping solutions and find the right desiccant for your needs.

Sandra Malouf is the President of Eurolog Packing Group and has spent her career focused on Industrial Packaging. With a proven track record of helping businesses avoid supply chain disruptions, Sandra’s visionary leadership elevates the industry. She’s committed to developing sustainable practices and continues to shape the future of industrial packaging by listening to the customer and offering unique solutions applicable to various industries across the world. The company’s main focus is temperature stabilization and moisture damage prevention in exports affected by extreme variations in global temperatures.

© 2025 Eurolog Packing Group