Shipping product in shipping containers? It’s vital to think about moisture control. Moisture in shipping containers can lead to rust, corrosion, and irreparable product damage. This can affect a wide range of belongings, from electronics to clothing, leading to significant financial losses. Without a moisture control strategy, your products may arrive completely destroyed, costing you money and damaging your customer relationships.

Fortunately, moisture control is possible with the help of desiccants. These compounds trap extra moisture in the air and prevent humidity from getting so high that it causes damage. They’re an essential addition to your shipment—but it’s important to choose your desiccants wisely.

The advantages of using desiccants for shipping containers include their ability to prevent moisture-related damage during transport, ensuring safe delivery by protecting various types of cargo from condensation and its harmful effects.

Read on to learn all about desiccants, how they manage moisture, and how to choose the best desiccant for your shipping container. Or, use the links below to jump ahead to a section of your choosing.

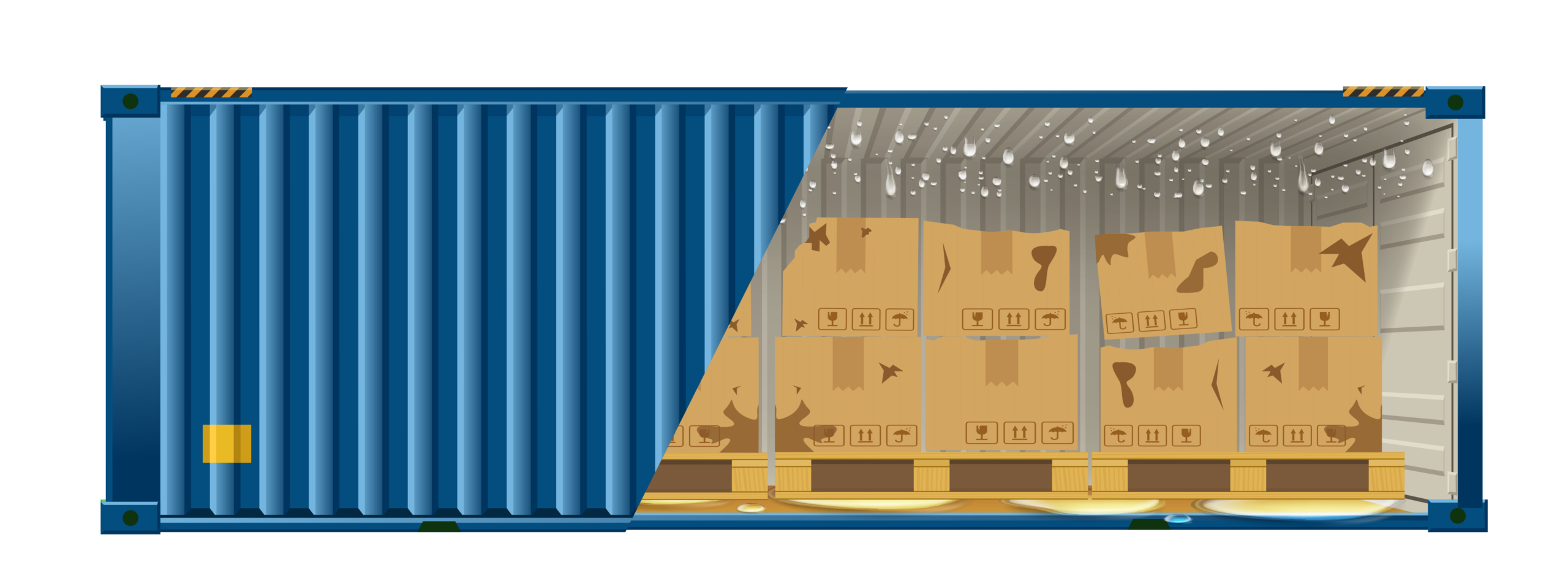

Moisture in a shipping container can do significant damage to your products and to your container’s integrity. Excess moisture can lead to the damaging effects of moisture, such as rust, corrosion, spoilage, and mold, mildew, and mold mildew.

Over the course of just a few days, a few mold spores can cover a surface of a few square feet, leading to the destruction of your product and significant loss of money. So, how do you protect your products as they travel to their destination?

Desiccants in shipping containers are one of the most effective types of moisture control. These materials are designed to attract and trap moisture from the atmosphere using hygroscopic materials such as silica gel and calcium chloride and prevent it from damaging your shipping container or products.

Moisture may be attracted to the surface of the desiccant, known as adsorption, or absorbed into the desiccant. Either way, shipping container desiccant keeps everything dry as it travels to its final destination. Desiccant packets are a common form used for this purpose.

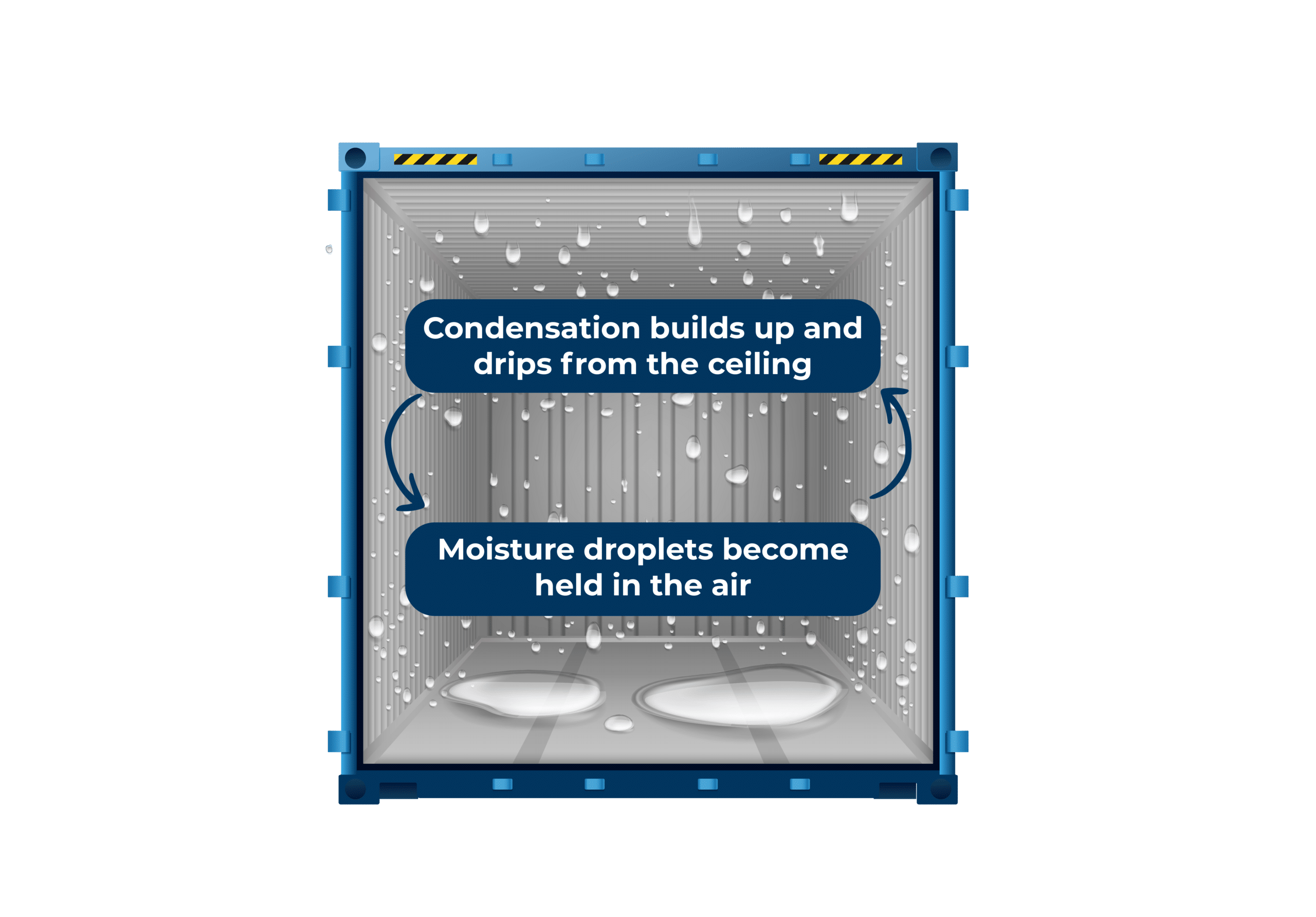

While it may seem insignificant, moisture is a significant and insidious issue in shipping containers. One common issue is cargo sweat, which occurs when condensation forms inside the container due to temperature fluctuations. Even the smallest amount of excess moisture can lead to the deterioration of your shipping container and your product.

Desiccants help manage relative humidity levels within shipping containers to prevent moisture damage, ensuring the safety and integrity of the products being transported. Moisture in a shipping container can come from a range of sources:

Desiccants trap moisture using two different processes:

Desiccants absorb or adsorb water molecules from the air, helping to decrease humidity and protect items from moisture damage.

As desiccants absorb moisture, they lower the humidity in the atmosphere and prevent it from reaching the dew point, the point at which humidity grows to 100% and condenses into water droplets. In doing so, desiccants protect your products and your shipping container.

Desiccants play a significant role in the safety of your product, so it’s important to select the most effective formulation. Choosing the right product for moisture absorption based on the specific needs of items stored is crucial for preserving their condition. Read on to learn how to select the best moisture absorbers for containers.

Desiccants can be made from a range of substances, both natural and manufactured. These desiccants are widely used in industrial applications to protect sensitive equipment and materials from moisture damage. Common types of desiccant include:

Selecting the best desiccant for shipping containers isn’t just above finding the desiccant that has the most effective absorption levels. Other considerations are important, too:

Additionally, it is crucial to choose environmentally safe desiccants that protect shipments from moisture damage during transport.

In addition to choosing the type of desiccant that’s best in your shipping container, it’s important to think about the format, too. Desiccant can come in a range of styles, each designed to absorb moisture in different ways. Some desiccant products even come with a hook for easy hanging and optimal placement within the container.

Desiccant packs can effectively keep food dry, prevent oxidation, and protect various items from moisture damage.

Desiccant bags can range in size from petite packets to large sacks of shipping container desiccants. Small desiccant bags work great inside individual product packaging to prevent condensation and lower humidity inside of products.

Desiccant bags protect stored items and stock by lowering humidity levels and preventing moisture damage, particularly in tightly sealed environments like storage containers.

Large desiccant bags, on the other hand, can be used to protect your container as a whole. Desiccant bags are available in several-pound sacks and are capable of absorbing pounds of moisture from the atmosphere.

To cover more surface area, look at desiccant blankets. These moisture absorbers for containers can be used to cover and protect cargo from “container rain,” falling droplets inside your container that are caused by condensation. Some desiccant blankets are designed to be suspended hooks on the ceiling to allow for circulation both above and below the blanket.

Desiccant pads are the best shipping container desiccant if you’re shipping product that is prone to leakage. As products leak, they can create rust and mold on the floor and walls of your container. Desiccant pads sit beneath your cargo and absorb this moisture before it can do any damage.

To enhance their effectiveness, it is important to use self-adhesive backing to secure the desiccant pads in place, ensuring they remain effective in moisture absorption.

Even the best desiccant bags aren’t effective unless they’re used correctly. Avoid these common pitfalls when selecting moisture absorbers for your shipping container.

It is critical to maintain a dry environment for storage containers to prevent issues such as mold mildew and product deterioration.

Different desiccants are suitable for different applications. Silica gel tends to be a good solution for small products like pharmaceuticals and electronic goods. It also does better in lower humidity environments. Calcium chloride, on the other hand, works better in high humidity.

Choose the best desiccant for your shipping container based on the types of product you’re shipping and the expected humidity on your route.

Desiccants use a quantity of measurement known as a “unit.” This is quantified as the amount of desiccant required to absorb 3g of moisture from a space with 20% humidity or 6g of moisture from a space with 40% humidity, at 77 degrees fahrenheit.

Desiccants can be particularly effective in larger areas such as basements, garages, and expansive storage areas, where managing moisture is crucial.

To calculate the amount of desiccant you need, multiply the number of cubic feet in your container by 1.2 units.

In order to properly absorb moisture in your shipping container, you’ll need to place desiccant bags with sufficient circulation around them, so they can come into plenty of contact with the moisture in the air. It’s also a good idea to place desiccant in the corners of your shipping container, as moisture tends to accumulate there.

Desiccants prevent the formation of condensation within shipping containers by lowering the dew point, which combats ‘container rain’ or cargo sweat and prevents moisture-related damage to various cargo types during transport.

Depending on your products, you may need to place desiccant in other places, too. If your products are leaky, put desiccant beneath them. If there’s a lot of air packed into your products, you should put desiccant inside their packaging.

No matter how well you prepare to absorb moisture in your shipping container, you’ll never know how effective you were if you don’t check your work. Install a wireless hygrometer in your shipping container so you can check its humidity levels along its journey.

Different conditions, such as temperature and humidity, can affect the performance and effectiveness of desiccants.

While you likely won’t be able to intervene if humidity gets too high along the shipping route, you will know if your moisture absorption methods didn’t work well enough. Next time you pack a container, you can try something different. That way, you’re always refining your methods.

Depending on the type of desiccant you use and the moisture levels in your shipping container, you may need to replace your desiccant at different rates. Some desiccants can absorb 100% of their weight in moisture, while others can absorb 300% and more.

Similarly, some desiccants are single-use only, while others can be dried out and reused. Some desiccants can be recharged by drying them out in an oven or microwave. It’s important to understand the capabilities of your desiccant and its moisture levels to determine when it’s time to replace your desiccant.

The primary sign of poor desiccant performance is the effects of moisture in your shipping container, whether that comes in the form of high humidity, pooling water, moldy product, or rust. If you’ve added the correct amount of desiccant and you notice these issues, you’ve likely selected poor quality desiccant.

A hygrometer can be a significant help in determining this, too. If your hygrometer measures higher than expected humidity throughout its journey, your desiccant may not be up to par.

The less moisture in your shipping container, the more effective your desiccant should be at keeping your container dry. Regular shipping container maintenance can help ensure excess moisture doesn’t build up inside. Maintaining a dry environment is crucial to prevent mold and deterioration of sensitive items and consumer goods.

Ensure that your shipping container seals properly and doesn’t have any cracks, dents, or other structural issues. Check your ventilation to verify that it’s circulating air effectively. If you identify issues, don’t risk the integrity of your product. Find a different container instead.

For the best selection of shipping container desiccants, there’s no better choice than Eurolog Packing Group. We specialize in moisture control in your shipping container, making sure your goods arrive at their destination free of mold and water damage.

By lowering humidity levels and dew points, our desiccants protect stored items from moisture damage, particularly in tightly sealed environments like storage containers. Discover how we can help ensure the integrity of your products today.

Sandra Malouf is the President of Eurolog Packing Group and has spent her career focused on Industrial Packaging. With a proven track record of helping businesses avoid supply chain disruptions, Sandra’s visionary leadership elevates the industry. She’s committed to developing sustainable practices and continues to shape the future of industrial packaging by listening to the customer and offering unique solutions applicable to various industries across the world. The company’s main focus is temperature stabilization and moisture damage prevention in exports affected by extreme variations in global temperatures.

© 2025 Eurolog Packing Group