If you’re shipping cargo in shipping containers, it’s important to be thinking about heat. Without proper systems in place, shipping containers can reach extremely high temperatures, damaging your products, packaging, and even the container itself. Not only can this be a major inconvenience, but it can also cost you a significant amount of money in lost product.

One effective method for regulating temperature and preventing moisture build-up in shipping containers is the use of foam insulation, specifically spray foam insulation. It offers a seamless application, high R-value, and long lifespan, making it ideal for temperature-sensitive items.

Fortunately, there are a number of techniques you can use to keep your shipping container cool. Utilizing thermal blankets and Styrofoam is a cost-effective way to maintain the integrity of your goods and ensure safe delivery every time.

Ready to learn more about how to keep a shipping container cool? Read on for information about excessive heat in shipping containers, why it occurs, and how to prevent it.

You may be surprised to learn that your shipping container can get hotter than most places on earth. In the right conditions, especially during the summer months, shipping containers can get up to 120 degrees fahrenheit on sea and 135 degrees fahrenheit on land as they travel to their final destination.

For any goods, these temps can cause damage, but perishable or temperature-sensitive products are particularly at risk. High temperatures can also lead to condensation issues, making it crucial to take steps to prevent condensation.

It takes a perfect storm of different factors for your shipping container to reach these exceptionally high temperatures. Factors that contribute to excessive heat in shipping containers include:

You may assume that, because no one travels inside your shipping container, the temperature inside doesn’t matter—but you’d be wrong. High heat in your shipping container can cause serious damage to your products, even if they’re not inherently temperature sensitive.

The impact of high temperatures on your shipment can be significant, affecting only the specific parts of the shipment that require temperature control.

The hotter your shipping container gets, the more damage can be done. Consequences of high heat in shipping containers may include:

To protect your cargo, it’s imperative to keep your shipping container cool. Fortunately, there are a number of cost-effective steps you can take to do so. Look into these techniques to protect your products.

Using an air conditioner can significantly improve the usability of shipping containers during hot weather, creating a comfortable and climate-controlled environment.

Thermal container liners are a simple solution to protect your product from extreme temperature. They fully line the inside of your shipping container, acting like a sleeve for your products. This insulates your shipping container and creates a sealed container to protect from extreme temps, condensation, and damage.

Thermal liners are designed for easy installation, making them a practical solution for temperature control. They are designed with multiple layers of insulating materials to regulate heat, including polyethylene and corrugated insulation materials. Foil liners on the inside and outside to both deflect heat and keep cool air in. This creates a much more protective enclosure than styrofoam, bubblewrap, or other insulation solutions.

Proper ventilation is also essential for keeping a shipping container cool. This can come in the form of passive ventilation, like an open vent that allows air to flow in and out, and active ventilation. These are typically solar-powered shipping container fans that blow hot air out of your shipping container and create a vacuum to suck new, fresh air in.

Windows, along with exhaust fans, can help reduce moisture and improve airflow within the shipping container. The best shipping container cooling strategy combines these two types of ventilation to keep inside temperatures cool.

Just as the foil on the outside of a shipping container liner deflects heat, so does reflective paint on the outside of your shipping container. These paints essentially create a mirror that projects the sun’s rays away from your container.

Reflective paint is particularly effective during sunny days, as it helps mitigate the heat absorbed by the container’s roof. The roof is a critical area because it absorbs a significant amount of heat, impacting the internal temperature.

Reflective paint is most commonly white or silver. Some include additional technology to block heat, too, like ceramic heat-reflective paints. We recommend opting for a marine-grade reflective paint that can effectively withstand the elements as your shipping container travels internationally.

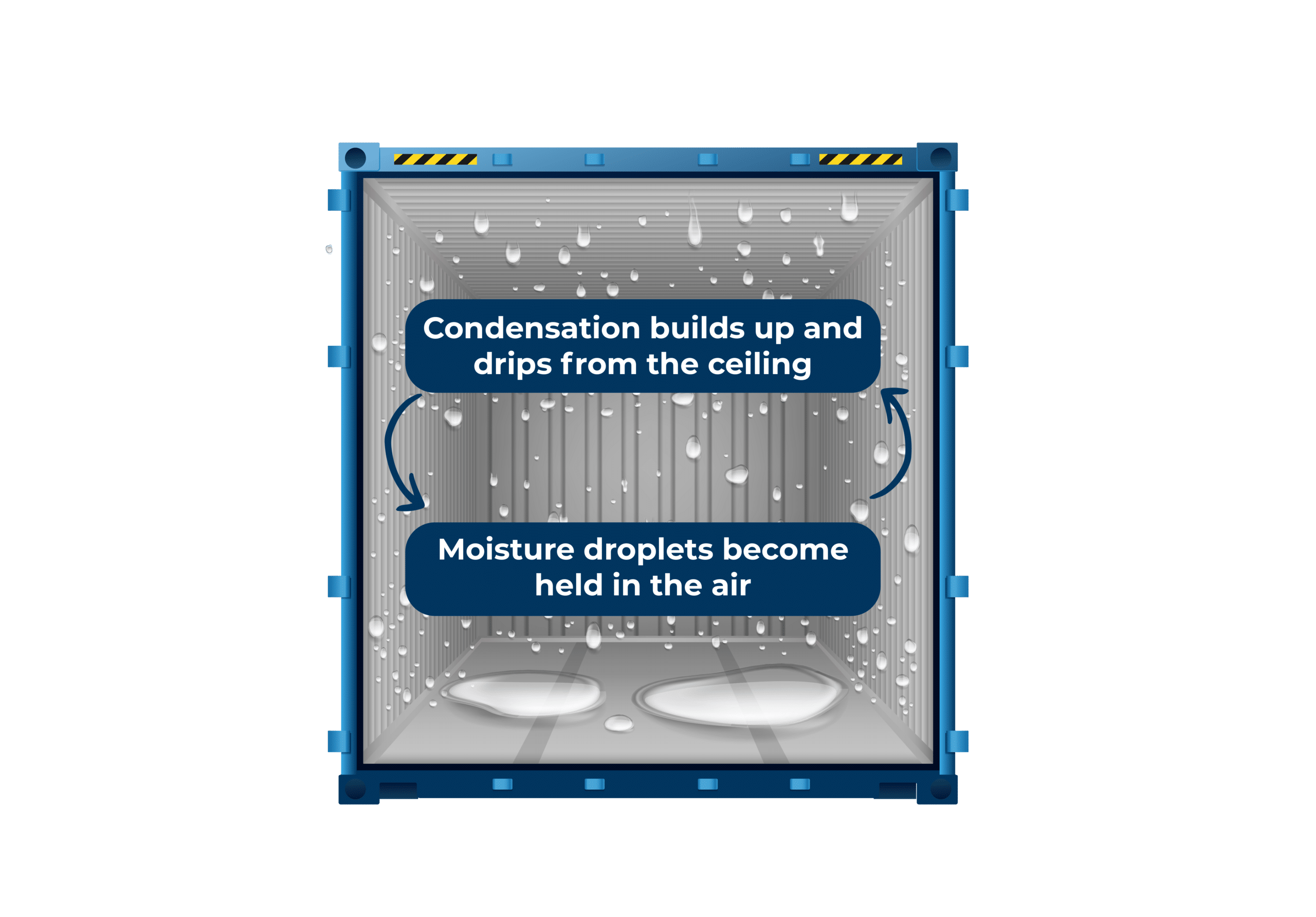

Another complication that comes along with high temperatures is high humidity. As humidity gets too high, it can create condensation and result in “container rain,” falling water droplets inside your shipping container, leading to moisture buildup and potential rust formation.

Using a moisture meter can help measure and manage humidity levels effectively, preventing condensation and moisture damage.

To prevent container rain from forming inside your shipping container, use dehumidifying container desiccants. These materials are designed to absorb excess moisture before it can do damage to your cargo.

Desiccants come in a range of different materials, each with their own best use cases. For travel through hot locations, we recommend using calcium chloride-based desiccants, an effective desiccant for absorbing moisture in high-humidity settings.

The best method to cool your shipping container is not a single technique, but a combination of multiple different strategies. By combining a reflective paint coating with effective ventilation and proper insulation options, you can create a system that effectively cools your shipping container.

Selecting the right insulation options based on climate and usage is crucial, and there are environmentally friendly insulation options available to create a comfortable, climate-controlled environment inside modified shipping containers.

Spray foam insulation is a superior method for temperature regulation and moisture control, creating a seamless barrier that minimizes energy loss.

If you’re shipping perishable goods, it’s best to ship your goods in a refrigerated shipping container, known as a “reefer.” These containers use a power source to refrigerate your container and keep its internal temperature low. Depending on the type of reefer, your shipping container may maintain a temperature ranging from 80 degrees to -22 degrees fahrenheit.

It is possible to install air conditioning in shipping containers to keep them cool as they travel internationally. These can be effective solutions in harsh climates or for goods that need to be maintained at a specific temperature, like medications or other temperature-sensitive cargo.

Using a dehumidifier alongside air conditioning can help manage humidity levels and reduce condensation.

Depending on the type of cooling system you have in place, maintenance requirements can vary. Desiccants to absorb moisture in your container should be replaced every trip. If you utilize a reusable desiccant, heat it after every trip to enable it to absorb moisture again.

Passive cooling systems like reflective paint, shipping container liners, and air vents should be inspected and refreshed every 6-12 months, depending on the number and length of trips. Active cooling systems like shipping container fans and air conditioning should be maintained every 3-6 months, depending on how often you use them. Proper maintenance of these systems is crucial to protect your equipment and ensure effective temperature control.

No matter where your shipping route takes your cargo, it’s important to use strategies to cool your shipping container. Shipping container liners, ventilation, desiccants, and reflective paints all keep your container’s temperature to a minimum and protect your goods. Additionally, maintaining the integrity of storage containers by preventing moisture can help avoid issues such as corrosion, structural damage, and mold.

Using various cooling methods offers many benefits, including energy efficiency, temperature control, and protection of sensitive items.

For the most advanced technology in shipping container cooling, meet Eurolog Packing Group. We’re committed to protecting your good, no matter their journey. Contact us today and discover why we have a 100% client satisfaction rate.

Sandra Malouf is the President of Eurolog Packing Group and has spent her career focused on Industrial Packaging. With a proven track record of helping businesses avoid supply chain disruptions, Sandra’s visionary leadership elevates the industry. She’s committed to developing sustainable practices and continues to shape the future of industrial packaging by listening to the customer and offering unique solutions applicable to various industries across the world. The company’s main focus is temperature stabilization and moisture damage prevention in exports affected by extreme variations in global temperatures.

© 2025 Eurolog Packing Group