Studies indicate that about 10% of container shipments suffer from moisture damage, leading to significant economic losses. This issue also results in other consequences such as environmental impact from cargo waste, increased insurance costs, extended claim processing times, and damaged customer relationships. Fortunately, high-quality solutions exist to prevent moisture damage from container condensation.

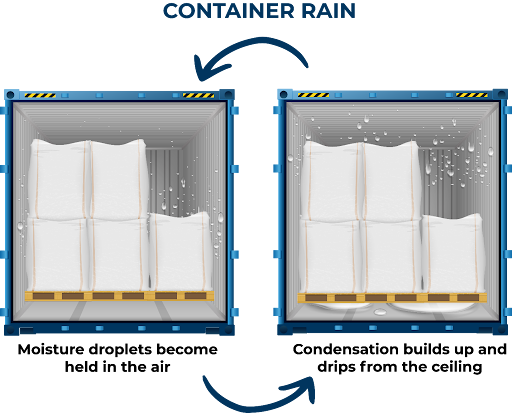

When a container is loaded, it contains moisture from the air, cargo, packaging, goods being shipped, and pallets. As the temperature rises, this moisture evaporates into the air, increasing the relative humidity inside the container. When the temperature drops, the moisture condenses into water drops on cooler surfaces of the container. This evaporation and condensation cycle, known as the container’s condensation cycle, leads to the “rain effect,” where condensation drops fall on the cargo, causing moisture damage. The condensation typically forms on the ceiling and walls of the container.

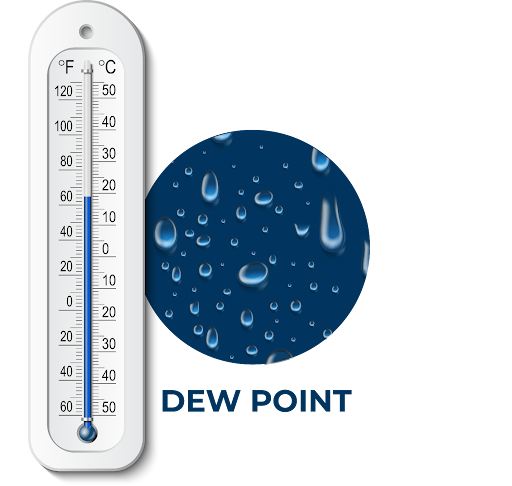

The dew point is the temperature at which air moisture condenses into water. It is directly related to relative humidity and is critical in understanding when condensation will occur inside the container. For example, at 25ºC with 70% relative humidity, the dew point is 19ºC. Maintaining temperatures below this point prevents condensation.

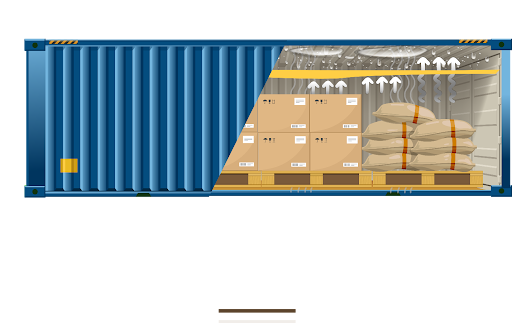

To break the condensation cycle and protect cargo, a combination of solutions is recommended, such as using Hybag Desiccants and condensation-absorbing Hyblankets to combat “container rain.”

The absorption capacities of desiccants vary depending on their design and formulation. The Hybag series offers a range of options, with absorption capacities from 100% to 350%. The quantity required per container depends on factors such as container size, weather conditions, transit duration, and the type of packaging used.

Using a combination of desiccants and absorbent blankets provides comprehensive protection against condensation damage, ensuring that cargo arrives in good condition. Hybags and Hyblankets offer a reliable, economical, and environmentally friendly solution for preventing moisture-related issues during shipping.

Sandra Malouf is the President of Eurolog Packing Group and has spent her career focused on Industrial Packaging. With a proven track record of helping businesses avoid supply chain disruptions, Sandra’s visionary leadership elevates the industry. She’s committed to developing sustainable practices and continues to shape the future of industrial packaging by listening to the customer and offering unique solutions applicable to various industries across the world. The company’s main focus is temperature stabilization and moisture damage prevention in exports affected by extreme variations in global temperatures.

© 2025 Eurolog Packing Group