Damage to your cargo shipment is a worst-case scenario for many. Not only does it result in significant financial loss, but it can also strain your customer and client relationships and result in supply chain delays. To protect your product and your business, it’s essential to take measures to minimize damage while shipping cargo.

Learn all about cargo damage, including what causes it, how to prevent it, and more.

Whether your cargo is traveling across the country or around the world, cargo damage can occur. This common challenge in the shipping industry can be devastating financially and damaging to your customer and client relationships. Proper warehouse conditions and layout are crucial in reducing cargo damages, as proper organization and cleanliness can prevent goods from being harmed.

Cargo that is improperly handled during transportation can suffer significant damage, compromising the container’s structural integrity. Additionally, adverse weather conditions can lead to severe issues such as containers being displaced or suffering water damage, particularly in ports exposed to extreme weather.

Cargo can be damaged at many points throughout its journey, from loading to shipping to unloading. Read on to learn common causes of cargo damage.

Improper handling during the loading and unloading of shipping containers is a leading cause of physical damage, affecting their structural integrity. Improper loading can also damage the container floor, as overloading or uneven weight distribution can cause the floorboard to sag or crack.

Additionally, rough seas can impact container stability during transport, leading to containers breaking loose from their lashings and potentially falling overboard, causing significant damage.

Corner castings are crucial for maintaining container stability, as these high-strength steel fittings located at the eight corners of shipping containers are essential for safe handling, stacking, and locking during transport.

If products aren’t padded correctly, they can get damaged during shipment. This may be caused by insufficient cushioning and protection inside individual products, in cases of product, or in the shipping container itself. Wherever the breakdown is, too much movement may cause products to break.

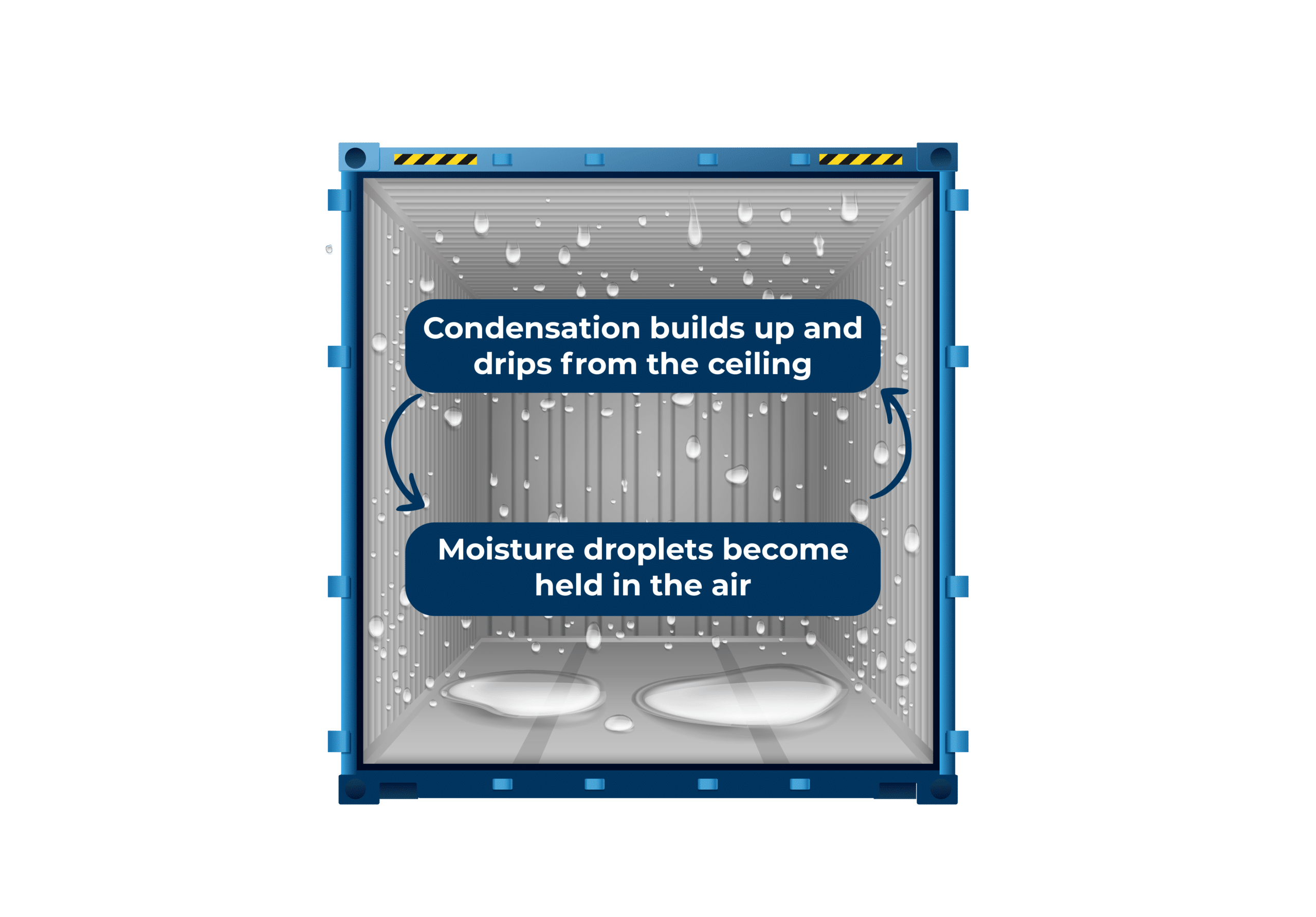

Humidity is a significant issue for cargo shipments. Without proper ventilation, moist, hot air gets trapped inside your shipping container. When the humidity gets too high, condensation occurs. This creates a phenomenon known as “container rain,” falling droplets of water inside your shipping container.

Container rain leads to a host of issues. It triggers the growth of mold on products and packaging, damages electronic goods, and corrodes metal.

In warm regions in the dead of summer, the temperature inside your shipping container can soar as high as 135 degrees. Extreme temperatures like these cause damage to all kinds of goods. Food perishes, electronics overheat, batteries fry, chemicals become ineffective—even canned goods become no longer safe to consume.

In order to load and unload your cargo, properly trained forklift operators, along with workers using cranes and other heavy machinery, are essential. Improper loading can lead to uneven weight distribution and cargo swaying, ultimately causing structural harm to both the cargo and the shipping container itself.

The use of twist locks to securely attach containers to trailers is crucial, as improper use can lead to serious accidents and cargo damage during transportation. Poor handling, particularly during the loading and unloading of heavy lift equipment, is a significant cause of damage. If used incorrectly, these powerful tools may damage palettes, packaging, and containers.

Proper training is necessary to prevent accidents and damages during loading, unloading, and transportation processes. Products can be dropped, knocked over, or otherwise mishandled, causing significant damage.

Your cargo shipment is only as good as the container it’s shipped in. By that we mean, damage to your products may come from damaged shipping containers. If your shipping container has bad seals, dents, cracks, rust, or any other structural damage, you may risk the integrity of your entire shipment.

Container repairs are essential for maintaining operational efficiency within logistics and transportation systems. Standardized damage codes streamline processes and reduce ambiguity during damage reporting, leading to quicker lead times for container repairs and improved overall efficiency.

To ensure the safety of your cargo, it is crucial to perform necessary repairs on containers that have sustained damage. Damaged containers can be repaired and reused for storage or living spaces, disposed of through recycling, or handled with environmental considerations, such as removing hazardous materials before disposal.

The main factor distinguishing cargo from freight is your shipment’s transportation method. “Cargo” refers to goods that are transported overseas or by plane. “Freight,” on the other hand, refers to goods transported by land on trucks or trains.

Minimizing damage while shipping cargo begins with ensuring that goods are properly packed to withstand transit conditions. Follow these tips to safely and effectively package your products.

Additionally, it is crucial to ensure that cargo is secured properly within the container to prevent swaying and potential damage, especially in challenging conditions like rough seas. Properly securing the cargo inside containers helps prevent physical strain and potential damage during transport.

Labeling packages to indicate their capacity for added weight is essential. This helps shippers make informed decisions and ensures that the structural integrity of the package is maintained, preventing damage to fragile contents.

It’s important to choose packing materials that are designed to protect the type of product you’re shipping. Use this list to guide your packaging choices:

While packaging may seem like an easy place to cut costs, don’t skimp on quality when it comes to these materials. High-quality packing materials may mean the difference between a shipment that arrives safely and one that arrives in shambles.

Once a product is loaded into your shipping container, it needs to be loaded correctly and effectively secured to minimize shipment damage. Securing a laden container properly is crucial to prevent damage during transportation. Follow these steps to do so:

To avoid cargo and container damage while loading and unloading your shipping container, follow these proper procedures:

Each time your cargo is passed between handlers or transportation providers, a new opportunity for shipment damage arises. Use this guidance to minimize damage while shipping your cargo:

Effective collaboration among all parties involved in logistics is essential to prevent cargo damage. This includes clear communication and teamwork to ensure timely deliveries and budget management.

Recognizing potential risks during transportation is crucial. By identifying these risks, proactive measures can be taken to protect both products and business relationships. When damage occurs, companies may face product and financial losses, highlighting the importance of risk assessment to mitigate potential damages.

Today’s technology has propelled cargo protection forward by leaps and bounds. Explore these tools that help prevent shipment damage. Standardized damage reports are crucial for effective data analysis, allowing companies to identify damage patterns, reduce repair costs, and enhance the integrity of claims data.

Regular inspections are essential for maintaining container integrity, as they help identify issues like corrosion, dents, and structural wear, thereby extending the lifespan of shipping containers and preventing costly damage.

There are a host of sensors and tracking devices that can keep you abreast of potential damage to your shipment along its route. These include:

For those who frequently ship cargo, a digital logistics tool can be a huge help. These all-in-one platforms provide real-time tracking, data analytics, communications tools, and more into a single dashboard for a high-level overview of your logistics.

Of course, some cargo damage derives from factors totally outside of your control, like the environment. Take these steps to minimize damage to your cargo shipment from weather:

Regular maintenance, including inspections and repairs, is essential to prevent environmental damage and prolong the lifespan of shipping containers.

Additionally, natural disasters such as hurricanes, earthquakes, and floods can cause significant damage to shipping containers and their cargo. Taking preventative measures can help mitigate the risks associated with these unpredictable occurrences.

Container yards serve as crucial locations for storing and processing containers before they are dispatched for shipping or returned. Proper handling and yard conditions are essential to prevent damages that can occur both within the yard and during subsequent transport.

Cargo damage can come from a range of sources. During loading and unloading, inexperienced forklift and crane operators may drop or knock over products, especially when handling heavy loads. They also may distribute weight poorly, causing instability inside your container. Products need to be padded correctly, too.

Too much empty space or poor-quality packing materials can lead to damage. Lastly, cargo damage can be caused by the elements, like extreme temperatures, condensation, and more. Accidents due to inadequate training and improper loading practices can also result in significant damage to containers, goods, and potentially public property.

Always select packaging that corresponds with your products. While lighter items can be packed in cardboard, heavier items require wooden crates and other heavy-duty packaging. Perishable goods should be vacuum sealed whenever possible.

Generally speaking, you should always choose the smallest possible packaging for your products. Leaving too much space inside a package can allow your goods to shift during transit, which often results in physical damage.

Fill empty space with packing paper, peanuts, bubble wrap, or other padding materials. Ensure that cargo is stacked properly to prevent shifting or collapsing during transportation, which can lead to damage.

Look to the following technologies to monitor your cargo as it travels to its destination:

For the best cargo protection available, discover Eurolog Packing Group. With the help of our shipping solutions, we ensure your goods make it to their final destination unscathed. Let us find a custom solution tailored to your needs to help minimize damage to your precious cargo.

Sandra Malouf is the President of Eurolog Packing Group and has spent her career focused on Industrial Packaging. With a proven track record of helping businesses avoid supply chain disruptions, Sandra’s visionary leadership elevates the industry. She’s committed to developing sustainable practices and continues to shape the future of industrial packaging by listening to the customer and offering unique solutions applicable to various industries across the world. The company’s main focus is temperature stabilization and moisture damage prevention in exports affected by extreme variations in global temperatures.

© 2025 Eurolog Packing Group