Sea bulk container liners form a protective layer between your shipping container and goods you’re shipping. Bulk container liners reduce the risk of contamination and leaks, helping protect your reputation and your bottom line. Loading and unloading spouts help you save time and streamline the dry bulk shipping process.

Our Kratobag series sea bulk liners are ideal for dry bulk shipping. We offer four types of liners with a handful of optional features to help you find the right solution for your shipping needs.

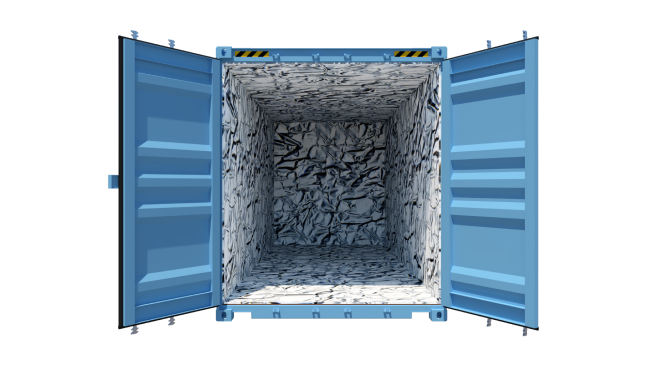

The Kratobag Series 5000 covers all six sides of your shipping container and features a wide opening for conveyor loading on the front bulkhead. The bottom spout makes unloading easy.They are commonly used for various meal exports.

The Kratobag Series 5000 is also available in a barless model. Because we’re able to eliminate the steel support bars, these sea bulk liners are more cost-effective.

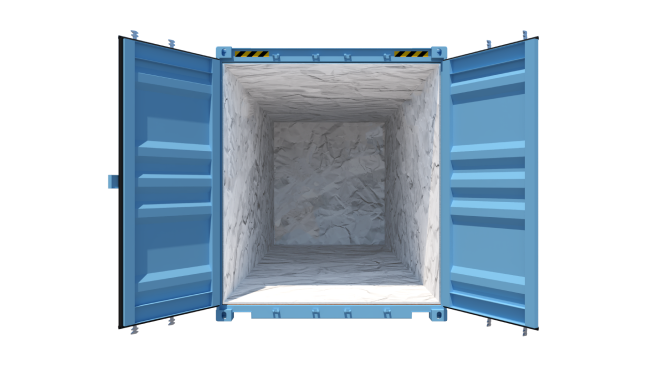

The Kratobag Series 5100 is an open-top liner that covers five sides of your shipping container and features a wide opening for conveyor loading on the front bulkhead. The bottom spout makes unloading easy.

Like the Series 5000, we offer a barless version of the Kratobag Series 5100 to help you maximize cost efficiency.

Our Temcore lineup is specially designed to create a reflective barrier to maintain stable temperatures inside your shipping container. If you’re shipping temperature-sensitive goods, Temcore liners offer the protection you need.

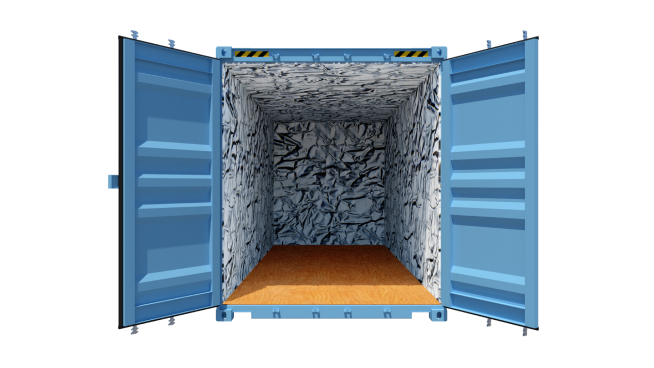

The Temcore 40’ Full Liner provides complete protection for 40’ shipping containers. These liners cover all six sides of your shipping container, keeping temperatures stable even when your cargo is exposed to extreme climates

The Temcore 20’ Full Liner is perfect for 20’ containers. Like our 40’ liner, the Temcore 20’ Full Liner covers all six sides to provide maximum protection against extreme heat and cold.

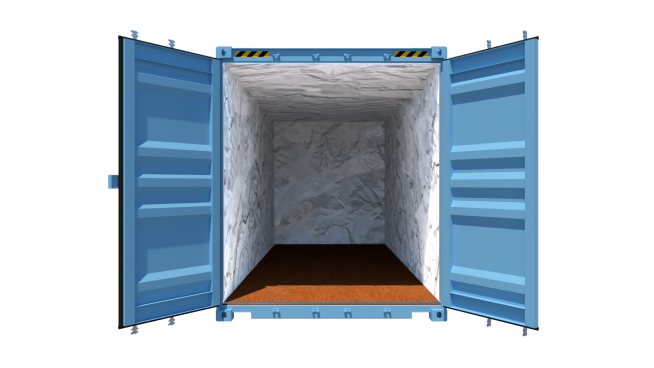

The Temcore 40’ HC No Floor Liner is very effective for rogue loading environments. You get coverage on five sides, everything but the floor. Your goods are protected from the most at-risk parts of a container that transfer heat.

The Temcore 20’ No Floor Liner is very effective for rogue loading environments. You get coverage on five sides, everything but the floor. Your goods are protected from the most at-risk parts of a container that transfer heat.

Moisture is a leading cause of cargo damage, but it’s also preventable. Our Kit Bond liners are engineered to minimize moisture inside your shipping container to prevent moisture damage and mold growth

Kit Bond liners are waterproof liners that protect your goods from damp floors and walls of shipping containers. Kit Bond liners are easy to install, and their high tensile strength means they don’t rip or tear and won’t cling to damp surfaces. These waterproof liners absorb moisture to help prevent mold and fungus growth inside shipping containers.

© 2025 Eurolog Packing Group