Hybag desiccant bags are specially designed to offer maximum absorption. They Hybag Square and Plus can absorb up to three times its weight in humidity, preventing the buildup of moisture and protecting your goods to a maximum. The Hybag Eco is designed to absorb 100% of it’s weight, it can be bought at both 1.5 and 2KG.

Maximum Absorption

High-Tech Breathable Fabric

State of the Art Fastening System

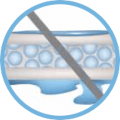

Zero Leakage—Guaranteed

Unrivelled Absorption

State of the Art Enclosed Hook

The Hypad is the ideal container floor solution if you are shipping any subject to leakage which can lead to rust on the container or mold on the floor. Hypads absorb excess moisture caused by condensation, leaks and spills. They are used over pallets or on container floors. Hypads are designed for easy installation, you simply place it over the pallet or on the container floor.

Gelfying Crystal Agents

High-Tech Fabric Linings

Unbeatable Ease

Anti-Moisture Lock

Preventing container rain is easy with our Hyblanket. Container rain is one of the leading causes of cargo damage during maritime shipments, but the revolutionary Hyblanket is designed to disrupt the condensation cycle by combining fast-absorbing ingredients. Our Hyblankets travel around the world with the most sensitive goods and high-risk goods.

Click-On-Top Hanging System

High-End Gel Formula

Breathable Membrane

Leak-Proof Design

© 2025 Eurolog Packing Group